Birmingham

Cadbury College

A transformative refurbishment project delivered in collaboration with Speller Metcalfe, Cadbury College showcases Axter’s commitment to high-performance, sustainable waterproofing solutions within the education sector.

- Client

- Speller Metcalfe

- Project type

- Refurbishment

- Project sector

- Education

- System categories

- Bitumen

- Accredited Installer

- LGX Roofing & Construction Ltd

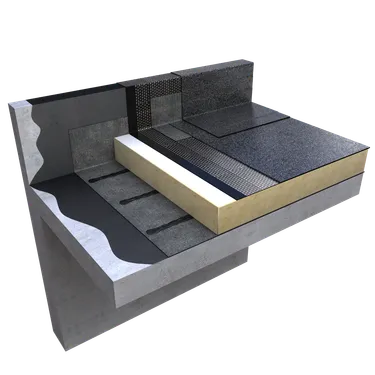

Systems in use

-

Excel®

A premium range of high performance reinforced bitumen waterproofing membranes, manufactured with the unique Alpa polymeric binder, making it our most technologically advanced RBM system.

-

Starcoat® R

Reliable and ready to use, Starcoat R is a unique, single component polyurethane bitumen resin, with integrated anti-root protection.

Project Overview

The project is a full strip and replacement of the existing 1,943m² roof area at Cadbury Sixth Form College that was undertaken to upgrade the building's thermal performance and meet current Part L Building Regulations. The existing reinforced bitumen membrane (RBM) system had exceeded its warranty period and required renewal to ensure long-term performance and compliance.

Cadbury College was carried out with Axter Ltd, who were integral with preconstruction design development, which consisted of circa 2000 sqm of full strip of existing coverings and installation of a new fully compliant RBM roof system to current Building Regulations, which ultimately gave a Goldshield warranty giving surety to the Client and end user.

Lee Greatrex, Managing Director at LGX Roofing & Construction Ltd

Axter’s Quality Assurance Technician and Technical Sales Manager carried out an initial site inspection and core sampling to assess the existing roof build-up. The survey confirmed that the existing deck was laid to falls, necessitating the use of flat board insulation combined with tapered gutters to improve drainage and achieve the target U-value of 0.16 W/m²K. This allowed us to meet both Part L and Part H to ensure that the refurbishment meets current Building Regulations.

The programme was scheduled around the school summer holiday period to minimise disruption. However, a portion of the works was completed during term time with strict operational measures in place to ensure minimal impact on students working beneath the affected areas.

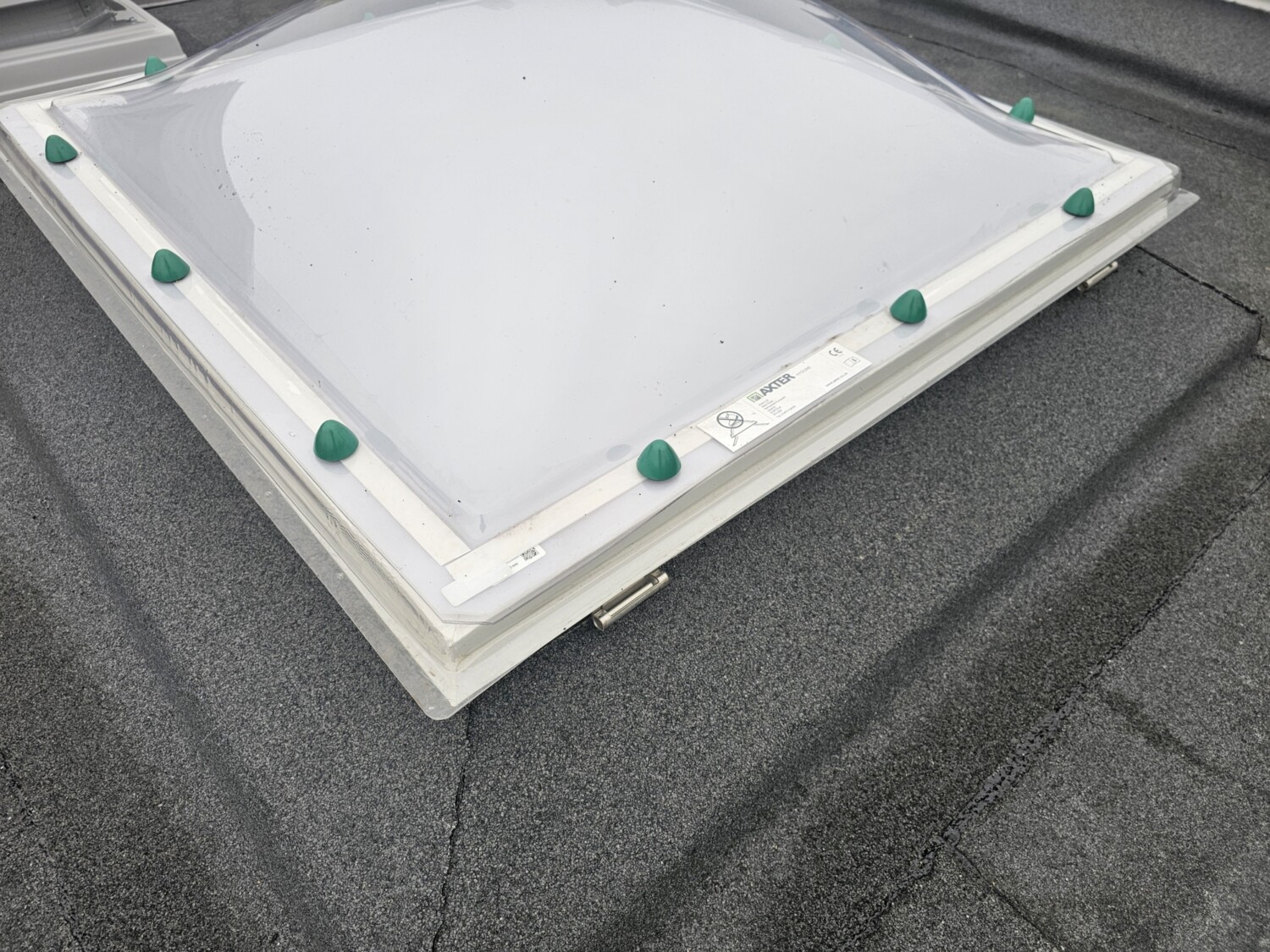

Axter supplied both standard and bespoke rooflights for the project. They attended the site to survey and deliver a bespoke design in line with client specifications.

Key Considerations

The communication with the main contractor, Speller Metcalfe, and roofing contractor LGX Roofing was essential for the smooth delivery of this project. The works were delivered in three phases, with each section of the roof carefully stripped and the new waterproofing system installed in sequence to ensure programme efficiency.

As the project was undertaken at a live education facility, a key challenge was managing site access, deliveries, and construction activities with students and staff present during part of the term. Strict coordination was required to minimise disruption to teaching and ensure safety.

The existing roof deck was a woodwool slab topped with asphalt. Axter conducted a U-value calculations to validate the thermal performance of the proposed system and eliminate the risk of condensation. A structural engineer was appointed to confirm the suitability of the deck for the proposed overlay works.

Integration of the new waterproofing system also involved managing complex design details around existing plant equipment and the installation of a new bespoke rooflight. Several areas contained asbestos, which required careful handling and detailing. A licensed asbestos contractor was engaged to enable the safe execution of works in these zones without risk to operatives.

To meet the insulation requirements of current Part L Building Regulations, certain upstand heights needed to be manually raised. These interventions were carried out in accordance with BS 6229:2018 to ensure compliance with threshold and detailing guidance.

Project solutions

Axter provided a fully compliant waterproofing solution tailored to the project’s logistical and technical demands. In out-of-sequence and hard-to-reach areas, Starcoat R cold-applied liquid waterproofing was used. This ensured safe installation around upstands, particularly where Safe2Torch guidance restricted the use of flame-applied systems. The liquid finish was colour-matched using charcoal granules to the RBM system, ensuring visual consistency across the roof area.

The specified Axter system offered full BBA certification and achieved Broof(t4) fire performance, ensuring compliance with current regulatory requirements while delivering long-term durability and client confidence.

This project was both technically demanding in terms of detail and time pressured in terms of sequenced programme demands requiring just-in-time deliveries due to restrictions of on-site storage and location.

Lee Greatrex, Managing Director at LGX Roofing & Construction Ltd

However, the overriding benefit to our business was the Axter single point of contact for the project in this instance, Joe Mogg, who was always available to assist and resolve the ongoing demands of design, procurement and project delivery to its conclusion, which was invaluable.

The Axter approach

Axter worked collaboratively with D5 Architects, Speller Metcalfe, and LGX Roofing to deliver a high-performing, compliant roofing solution supported by standard and bespoke detailing where required. Regular attendance at design team meetings and site visits enabled Axter to provide the ongoing technical and programme support, all under the assurance of our GoldShield guarantee.

QA support was provided throughout the project to ensure full compliance with the specification and consistently high standards of workmanship. Axter also coordinated the supply chain, managing key partners to guarantee the timely delivery of both standard and bespoke components.

All materials were procured and supplied via Axter Ltd inclusive of all system waterproofing materials, insulation, both flat and cut to falls, rooflights some 56 number in total varying in sizes and a bespoke 21-meter linear rooflight to suit project requirements.

Lee Greatrex, Managing Director at LGX Roofing & Construction Ltd

Axter design input, along with our design team catering to the bespoke project requirements was invaluable and gave a seamless delivery throughout, this coupled with excellent on-site support via their quality management team which was first class.

Quality of the formatted Axter pricing documents made it easy in terms of order placement with a very efficient and friendly orders department.

Learn more about why Axter stands out as a trusted leader in flat roofing solutions.

For more information on how Axter's roofing systems can benefit your next project, please contact our team.