Nuneaton

George Eliot Hospital

The NHS Estates Team required a new office space and workshop area and proposed the refurbishment of an existing building.

- Client

- NHS

- Project type

- Refurbishment

- Project sector

- Medical & Healthcare

- Accredited Installer

- Empire Roofing Systems Ltd

Systems in use

-

Hyranger®

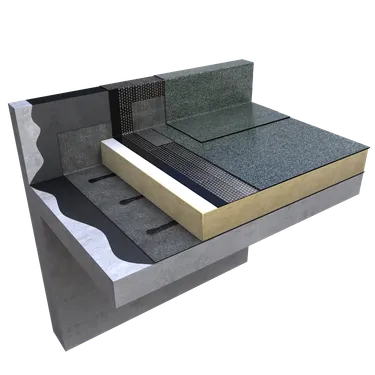

Hyranger is a well established and trusted flat roof waterproofing system, comprising polyester reinforced SBS polymer modified bitumen membranes, developed to guarantee strength, stability, performance and cost efficiency.

-

Starcoat® PMMA

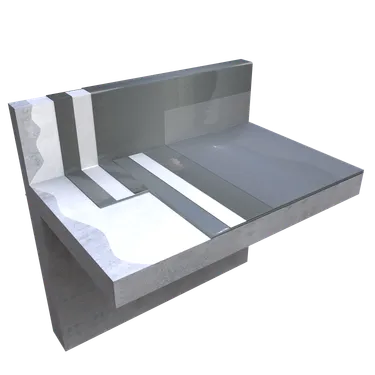

A flame free and rapid cure, two component polymethyl methacrylate (PMMA) resin waterproofing system that provides a fully adhered waterproofing layer.

Overview

Axter Ltd were instructed by William Gough & Sons Ltd to produce a design for six roof areas, following a site survey report. The project included a mixture of new build and refurbishment areas, comprising of various systems and design requirements. This included a cut to falls insulation design to comply with Part H and BS 6229:2018. Roof A, the focus of this case study, had a series of convex or ‘barrel roofs’, requiring bespoke detailing and careful design to achieve robust detailing and the required U-value.

The project value was circa £1 million. This included all building works and a strict budget for the roofing package, which was achieved. The programme for the works was 16 weeks and completed in Autumn of 2022, to the required deadline.

The successful project was also nominated for a National Federation of Roofing Contractors (NFRC) award 2023.

Challenges

Axter were appointed at RIBA Stage 2 to undertake site surveys and work alongside the Principal Designer as Designer under the Construction Design and Management Regulations 2015.

The existing asphalt had shown signs of cracking and blistering, and the outlets were damaged from vegetation growth from a lack of maintenance. New outlets were installed with leaf guards, allowing free flowing water whilst preventing blockages.

The proposed office section of the works required thermally upgrading to comply with Building Regulations: Part L. The U-Value requirement was 0.18W/m2K which could be achieved with a 120mm PIR flat board. Due to the curved profile of the roof, installing the insulation below deck level was considered. However, due to an inadequate ceiling height this was disregarded.

Furthermore, this would have resulted in the development of interstitial condensation. Further design solutions had to be considered. To bend a 120mm board would have required multiple cuts to the insulation so the decision was made to split this into two thinner boards to achieve the radius more easily.

When split into two layers the requirement changed to 2 x70mm boards (140mm total) as worked out using U-Value calculations by the in-house design team at Axter. A timber hard edge was introduced to abut the insulation at the building perimeter to separate the façade and the main field area.

Systems and products

Axter’s Hyranger multi-layer RBM system was used across all six roof areas. The system is fully BBA and BRoofT4 compliant, and achieves a guarantee period of 20 years. For this project, Axter’s Goldshield Guarantee was chosen, which covers materials, workmanship and design liability. This was overseen on site by Axter’s Quality Assurance team, who audited the project inclusive of the installation, safety and general management of the roofing works.

Axter Starcoat PMMA was used as a cost effective solution to coat the copper fascia and provide a fresh and seamless look to the exterior of the building.

Solutions

The Axter Hyranger multi-layer RBM system was installed using traditional gas driven torches to fully bond the (AVCL) Air and Vapour Control Layer and cap sheet layers. The underlayer was installed over a tissue faced PIR and therefore needed to be self-adhesive in order to reduce the risk of fire, complying with NFRC Safe2Torch guidelines. A cold applied Starcoat PMMA liquid was installed to the façade to achieve a seamless and cost-effective upgrade.

The Axter Quality Assurance Team regularly attended site and were in constant communication with the appointed Axtershield Installer, Empire Roofing operatives, to ensure that the system was being installed correctly and to the expected standards in order to achieve the Goldshield guarantee required by the client. To achieve the guarantee level, all materials and workmanship had to be installed as per the Axter specification.

The site agent from the main contractor was also regularly on site to oversee the project and ensure that deadlines and timescales were being achieved to keep the build on target for completion. The installation of the multiple roof areas was achieved to exceptional standards leaving the client very impressed with the workmanship.

William Gough & Sons Ltd were very impressed with Axter Ltd on our first scheme with them at George Eliot Hospital in Nuneaton. The requirements of the scheme, which included a complex barrelled roof were investigated on site early in the design phase of the project and Axter’s recommendations were swiftly proposed and agreed with the client’s Architect. Once the design requirements had been established one of Axter’s approved installers were employed by us to very successfully deliver the scheme. The 20 year Goldshield guarantee provided for the Reinforced Bituminous Membrane system offered peace and mind to our client.

Chris Hinton, Senior QS, William Gough & Sons