Derby

Nightingale Quarter Block E6

Nightingale Quarter is a £175 million regeneration project in Derby, transforming a former hospital site into a vibrant mixed-use community. The final phase focuses on Block E6 – a key residential building delivering more than 100 new homes. With winter fast approaching and tight deadlines, Wavensmere Homes needed a robust roofing solution that could be installed quickly without compromising quality or long-term performance.

- Client

- Wavensmere Homes

- Project type

- New Build

- Project sector

- Residential

- System categories

- Bitumen

- Accredited Installer

- Empire Roofing Systems Ltd

A system designed for performance, speed, and sustainability

Facing tight deadlines and complex technical requirements, Wavensmere Homes chose Axter to design and supply a high-performance flat roofing solution that could be installed quickly while ensuring long-term durability and reliability.

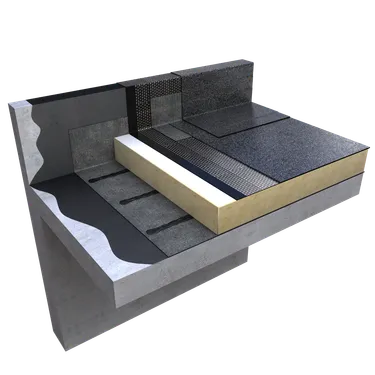

Axter’s Excel® warm roof system, featuring multi-layer Reinforced Bitumen Membranes (RBM), was selected for its proven robustness, ease of installation, and dependable performance. Wavensmere Homes required a solution backed by a comprehensive guarantee, with fast installation times and responsive technical support – all of which Axter delivered.

Systems in use

-

Excel®

A premium range of high performance reinforced bitumen waterproofing membranes, manufactured with the unique Alpa polymeric binder, making it our most technologically advanced RBM system.

Being involved in the Nightingale Quarter, a key regeneration project in Derby, is a real honour. Being selected by Wavensmere Homes for such an important development reflects the quality and robustness of our roofing systems and the value of the comprehensive service that we offer. With Axter’s 30-year Goldshield guarantee backing the system – and our reputation as a trusted provider – we were able to give the developers full confidence that our system would perform.”

Joe Mogg, Technical Sales Manager at Axter

The specification included a tapered insulation scheme to ensure effective drainage compliant with BS6229:2018, alongside Broof(t4) fire certification.

Excel® also aligned with the project’s environmental goals. The finished roof will support solar PV panels and battery storage to capture and reuse clean energy, contributing to sustainable living for more than 1,000 new residents.

“It was critical to install a robust bituminous system capable of handling the additional load of the PV installation while fully complying with all necessary regulations,” explains Joe. “The Excel system met all performance criteria and proved to be the optimal solution.”

Adapting to client deadlines and weather conditions

The project timeline was particularly tight following the concrete slab pour in December 2024, with winter weather adding unpredictability. Axter’s Quality Assurance (QA) team responded swiftly, conducting moisture tests within three weeks to confirm that the slab was ready to accept the waterproofing system, which was earlier than the typical 28-day curing period.

“At Axter, we are flexible and responsive to both client deadlines and weather challenges,” explains Joe. “Our on-site QA support ensured the contractor could proceed safely and confidently, keeping the project on schedule.”

Full Quality Assurance and supply chain coordination

Throughout the project, Axter provided continuous QA support to maintain compliance with specifications and workmanship standards. The team also coordinated the supply chain to ensure the timely delivery of materials and bespoke items.

Collaborative design support from concept to completion

Working closely with Gould Singleton Architects, Axter supplied detailing packs and advised on bespoke solutions where needed. This collaborative approach ensured all detailing was fully compliant with British Standards and aligned with the building’s design intent.

“Our technical team acts as an extension of the architect’s design process,” says Joe. “We support from concept through to delivery, helping protect specification integrity and project success.”

Learn more about how Axter supports architects from concept to completion, ensuring project success.

Installed by trusted professionals

The roofing works were completed by Empire Roofing, an Axter-accredited installer. This ensured that the system was installed to the highest possible standard by a team trained in Axter’s products and protocols.

Axter-accredited installer network means you can trust that the work has been completed by vetted professionals, with full system guarantees providing peace of mind.

Learn more about the importance of working with an accredited installer.

The Axter approach

Whether you are planning a new installation, a replacement, an upgrade, or some repairs, Axter offers a complete package: high-quality materials, a dedicated team, a network of expert installers, and guarantees you can count on.

Learn more about why Axter stands out as a trusted leader in flat roofing solutions.

Explore more of our case studies:

- An ambitious and large-scale replacement programme at a global landmark building, Baitul Futuh Mosque

- A rooftop design that combines renewable energy generation with a living roof to improve local biodiversity, St Mary’s Road, Peckham

- A complete refurbishment of a residential block facing serious structural and waterproofing challenges, Abbots Avenue West

- The first phase of a major redevelopment on the site of the former Kodak factory in Harrow, Aperture Works

For more information on how Axter's roofing systems can benefit your next project, please contact our team.